The Height of the Circle: Engineering is very different from fairy tales.

Often in Mountain Bikes you see unbalanced rims with a very low or too high profile in order to change the wheel stiffness. Our profiles have variable heights from 25 to 27mm.

Let's immediately dispel a false myth, not supported by any numerical data .

If you remain in a logical range of width/height ratio in section, the height of a carbon rim has a very relative influence on the torsional stiffness of the rim, and much lower if we insert it in the wheel system with latest generation composites .

It is obvious that other (much more important) factors being equal, rims that are very unbalanced in height (too low or high in relation to the width) will result in structurally overloading one or the other area of the profile, often obtaining the opposite effect to the desired one.

If we want to draw up a ranking of the structural characteristics of a rim that impact on torsional stiffness, profile height is around 5th place.

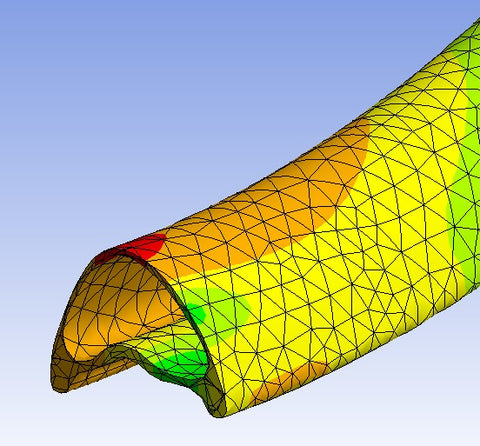

So if you ask what height our grooves have, the answer is very simple (getting there was very complex): it is the best one calculated on the basis of FEM simulations , in relation to the profile width and the dynamic characteristics we want to obtain from our wheel systems.

It's called planning: everything that cannot be demonstrated numerically is hot air.

Innovation, not Imitation™